Why Manufacturers Choose Asset Tracking RFID Software

Introduction

Manufacturing is all about precision, speed, and timing. Even the smallest delays — like a missing tool or misplaced raw material—can ripple across the production line and slow everything down. That’s why asset tracking has become a critical requirement. From heavy machinery and tools to raw materials and finished goods, manufacturers must manage thousands of moving parts daily. Effective asset tracking ensures operations run smoothly, costs stay under control, and productivity doesn’t take a hit.

![]()

For many years, manufacturers relied on manual logs or barcode-based systems to track assets. While these methods provided some level of visibility, they often introduced errors due to mis-scans, misplaced items, or delays in data entry. The result? Lost time, higher costs, and lower efficiency.

This is where RFID in manufacturing has emerged as a game-changer. By automating data collection and offering real-time visibility, RFID is transforming how manufacturers manage their operations.

The Need for RFID in Manufacturing Asset Tracking

Modern manufacturing facilities are complex ecosystems that depend on seamless coordination between machines, tools, materials, and workers. This complexity makes accurate asset tracking more important than ever.

- Growing Complexity of Production Environments: Multiple production lines, warehouses, and assembly areas require accurate, real-time monitoring. Without RFID, bottlenecks and misplacements become common.

- High-Value Equipment, Tools, and Materials: Manufacturers deal with expensive equipment and critical raw materials. Misplacing or losing them can directly impact profits and production timelines.

- Compliance, Safety, and Maintenance Requirements: Many industries face strict regulations regarding asset usage, calibration, and maintenance. RFID ensures compliance by providing accurate, traceable records.

- Limitations of Traditional Methods: Barcodes and spreadsheets require line-of-sight scanning and manual intervention, which can’t match the speed, accuracy, and automation provided by RFID.

Key Benefits of RFID Asset Tracking Software for Manufacturers

Implementing RFID-based asset tracking software offers several advantages that directly improve productivity and reduce costs.

![]()

Real-Time Visibility of Assets

With RFID software, manufacturers gain immediate insight into the exact location and status of every asset, whether it’s equipment, raw material, or finished goods. This visibility reduces the time wasted on searching for misplaced items, ensures smoother workflows, and minimizes costly production delays.

Improved Accuracy and Reduced Human Error

Manual tracking and barcode scanning often lead to mis-scans, duplication, or missed entries. RFID automates the data capture process, ensuring information is recorded with precision. This level of accuracy eliminates errors, reduces rework, and builds greater trust in the asset data across the organization.

Automation of Audits and Cycle Counts

Auditing assets manually can be time-consuming and disruptive to operations. With RFID, audits and cycle counts can be completed in minutes instead of days. Automated scanning improves efficiency, frees up labor for higher-value tasks, and provides up-to-date records that support compliance and reporting.

Predictive Maintenance Through Data Insights

RFID software doesn’t just track location — it also records usage patterns. By analyzing this data, manufacturers can anticipate when machines or tools need maintenance before breakdowns occur. This predictive approach reduces downtime, lowers repair costs, and extends the overall lifespan of valuable equipment.

Scalability Across Different Manufacturing Sites

As businesses grow, asset tracking needs expand across multiple locations. RFID software offers scalability, allowing manufacturers to start at one facility and expand to a global network without disruption. This flexibility ensures consistent, centralized visibility and control, no matter how large or complex operations become.

Why Manufacturers Choose TagMatiks RFID Software

When it comes to RFID asset tracking, manufacturers need solutions that are flexible, configurable, and scalable. TagMatiks offers two versions to meet different needs: TagMatiks AT Lite for smaller deployments and pilot projects, and TagMatiks AT for enterprise-wide operations.

TagMatiks AT Lite

TagMatiks AT Lite is designed for small to mid-sized manufacturers or businesses just starting with RFID.

- Flexibility: Quickly deploy across a single facility or pilot project without complex setup.

- Configurability: Customize fields to track essential details, such as tool calibration, batch numbers, or asset categories.

- Ease of Use: Lightweight interface that’s simple for teams to adopt and operate daily.

- Offline Support: Works even in areas with limited internet connectivity, ensuring continuous tracking.

- Integration: Compatible with existing ERP or MES systems for seamless data flow.

In short, TagMatiks AT Lite lets manufacturers test and scale RFID without heavy upfront investment while still gaining real-time visibility and control over their assets.

TagMatiks AT

TagMatiks AT is a full-featured enterprise-level solution, ideal for large-scale manufacturing operations and multi-location facilities.

- Scalability: Manage thousands of assets across multiple plants or warehouses with centralized control.

- Advanced Configurability: Track complex asset information, maintenance schedules, usage history, and compliance data.

- Compliance-Ready: Built-in features support audits, safety standards, and regulatory reporting.

- Automation & Analytics: Provides detailed reports, predictive maintenance insights, and workflow automation.

- Integration: Deep integration with ERP and MES platforms ensures smooth, real-time operations across the organization.

With TagMatiks AT, manufacturers gain a comprehensive view of their entire asset lifecycle, helping optimize efficiency, reduce losses, and support long-term operational growth.

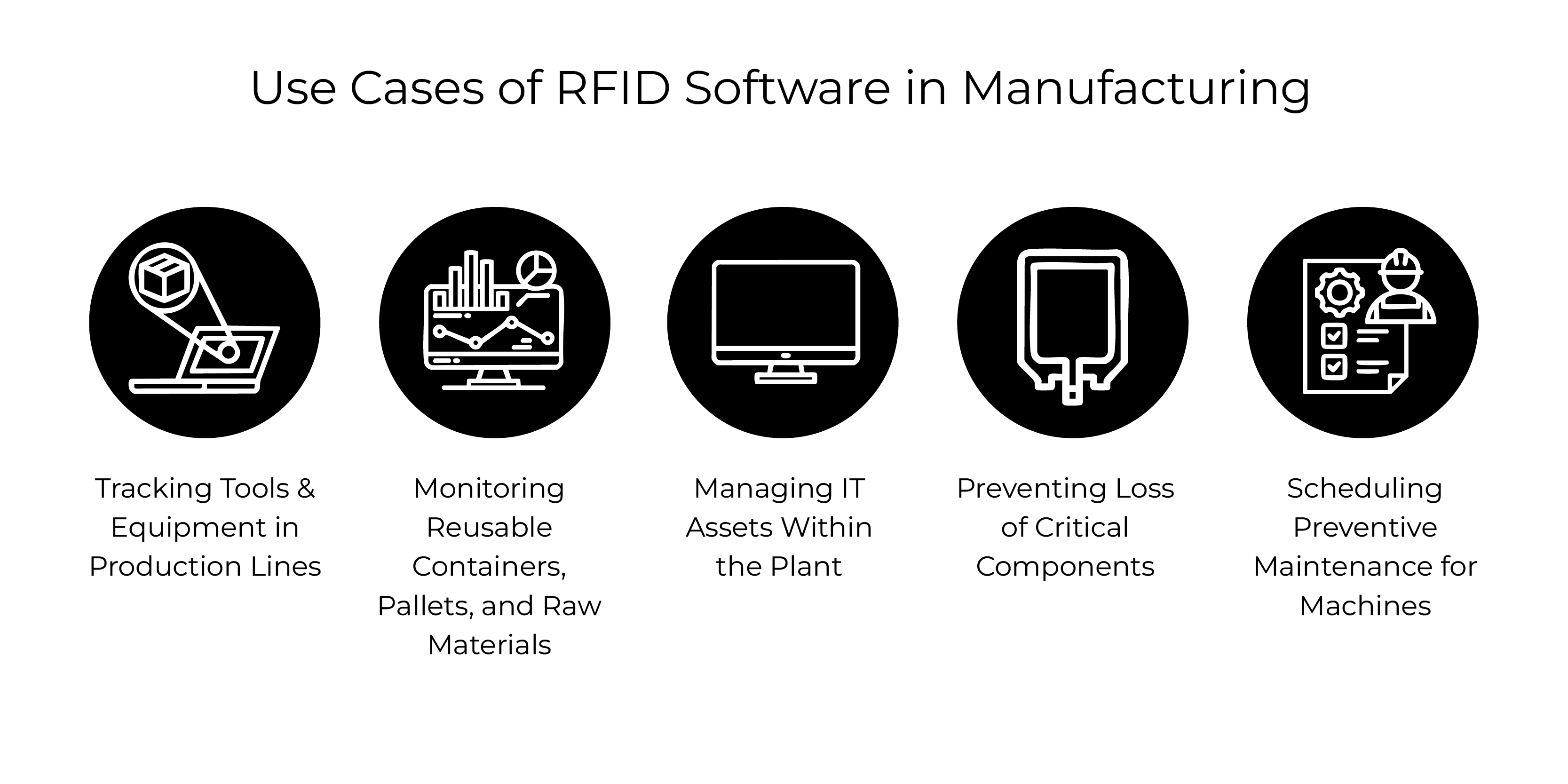

Use Cases of RFID Software in Manufacturing

RFID asset tracking isn’t just about knowing where assets are—it enables manufacturers to optimize every stage of operations. In fact, the adoption of RFID in manufacturing has opened up new possibilities for streamlining processes, reducing errors, and improving visibility across facilities.

Tracking Tools and Equipment in Production Lines

RFID ensures that every essential tool and piece of equipment is accounted for in real time. By tracking items on the production floor, manufacturers can prevent delays caused by missing tools, keep workflows smooth, and maintain consistent output quality.

Monitoring Reusable Containers, Pallets, and Raw Materials

Manufacturers often lose track of containers, pallets, and raw materials during movement or storage. RFID provides full visibility across the supply chain, reducing losses, improving inventory accuracy, and ensuring that materials are always available when needed for production.

Managing IT Assets Within the Plant

IT devices like laptops, handheld scanners, and network equipment play a key role in modern manufacturing operations. RFID tracking helps maintain an accurate inventory of these assets, prevents misplacement, and ensures that critical systems remain operational without disruption.

Preventing Loss of Critical Components

High-value components or spare parts are vulnerable to theft or misplacement. RFID monitoring provides real-time alerts and tracking, helping manufacturers safeguard these assets, avoid production interruptions, and reduce costs associated with replacing lost items.

Scheduling Preventive Maintenance for Machines

Rather than relying on fixed maintenance intervals, RFID tracks machine usage and performance data. This allows manufacturers to schedule preventive maintenance precisely when needed, minimizing unexpected breakdowns, reducing downtime, and extending the lifespan of critical equipment.

Choosing the Right Software: TagMatiks AT vs AT Lite

Selecting the right solution depends on the scale and needs of the manufacturer.

TagMatiks AT Lite

Selecting the right RFID solution depends on the size, scale, and specific needs of a manufacturer. TagMatiks AT Lite is ideal for small manufacturers, pilot RFID projects, or organizations tracking a limited set of assets. It offers a simple setup with a user-friendly interface and even supports offline operation in environments with limited connectivity, making it perfect for quick deployments and smaller facilities.

TagMatiks AT

On the other hand, TagMatiks AT is designed for large manufacturers and multi-location enterprises that require full-scale RFID management. It provides comprehensive asset lifecycle tracking, advanced analytics, and preventive maintenance scheduling, making it an ideal solution for organizations that need deep integration with ERP or MES systems and centralized control across all facilities.

Conclusion

In a highly competitive landscape, manufacturers cannot afford to rely on outdated tracking methods. RFID software has become essential for ensuring operational efficiency, reducing costs, and staying ahead of the competition.

With TagMatiks AT and TagMatiks AT Lite, manufacturers have the flexibility to choose a solution that matches their current needs—while being confident it can grow with their future demands.

Whether you’re a small manufacturer looking to pilot RFID or a large enterprise aiming for complete asset visibility, TagMatiks has you covered.

Frequently Asked Questions (FAQs)

Why do manufacturers prefer RFID software for asset tracking?

RFID software provides real-time visibility of assets, reduces manual errors, and improves operational efficiency across manufacturing facilities.

How does RFID software improve production workflows?

By automating asset identification and movement tracking, RFID ensures faster cycle times, reduced bottlenecks, and smoother production processes.

What types of assets can be tracked with RFID software?

Manufacturers use RFID to track tools, machinery, raw materials, finished goods, and returnable transport items (RTIs).

Can RFID software help reduce asset loss and theft?

Yes. RFID creates a digital trail of asset movement, making it easier to detect unauthorized removal or misplacement.

How does RFID software enhance inventory accuracy?

RFID enables bulk scanning without line-of-sight, ensuring precise inventory counts and reducing discrepancies compared to manual methods.

Does RFID software integrate with existing manufacturing systems?

Absolutely. RFID software connects with ERP, MES, and warehouse management systems, ensuring seamless data flow across operations.

Is RFID software scalable for different manufacturing sizes?

Yes. RFID solutions can be tailored for small workshops, mid-sized factories, or large enterprise-level manufacturing plants.

What are the overall benefits of RFID asset tracking software for manufacturers?

Benefits include real-time visibility, reduced losses, improved compliance, optimized workflows, cost savings, and stronger supply chain efficiency.

Recent Posts

-

What Is an RFID Self-Checkout System? A Complete Guide for Retailers

Introduction Retail checkout has seen a remarkable transformation over the years. What started with …Feb 27th 2026 -

Upgrade from Barcodes to RFID on Shopify: A Retailer’s Guide

Retailers on Shopify are beginning to question whether barcodes are enough. With rising customer exp …Feb 24th 2026 -

Work-in-Progress Tracking with RFID in Manufacturing

Introduction In manufacturing, Work-in-Progress (WIP) refers to items that are in various stages of …Feb 20th 2026