RFID Solution in Warehouse

RFID Solution in Warehouse

How RFID Solves These Challenges

RFID addresses warehouse challenges by enabling automated data capture, which reduces human error and ensures faster, more accurate inventory tracking. With real-time location visibility, items are always accounted for, while improved picking and shipping accuracy minimizes costly mistakes. Additionally, RFID helps optimize space and resources through smarter, data-driven planning, making warehouse operations more efficient and reliable.

Key Benefits of RFID in Warehousing

Accuracy & Visibility

RFID ensures up to 99% inventory accuracy, giving warehouses real-time visibility of stock levels and reducing errors caused by manual counts or barcode scanning.

Increased Efficiency

By automating data capture, RFID cuts cycle count time by up to 80%, freeing staff to focus on more valuable warehouse operations and fulfillment tasks.

Cost Savings & ROI

RFID reduces labor costs, minimizes human errors, and prevents lost or misplaced items, delivering a strong ROI through streamlined warehouse operations and better inventory control.

Better Decision-Making

Real-time RFID data empowers managers to make smarter, data-driven decisions about inventory, space utilization, and workforce allocation, improving overall warehouse productivity and performance.

Enhanced Customer Satisfaction

With faster order processing and reliable fulfillment accuracy, RFID helps warehouses deliver goods on time, reducing delays and enhancing customer trust and satisfaction.

RFID Solutions for Warehousing

At RFID4U, we provide end-to-end RFID solutions tailored for warehouse environments:

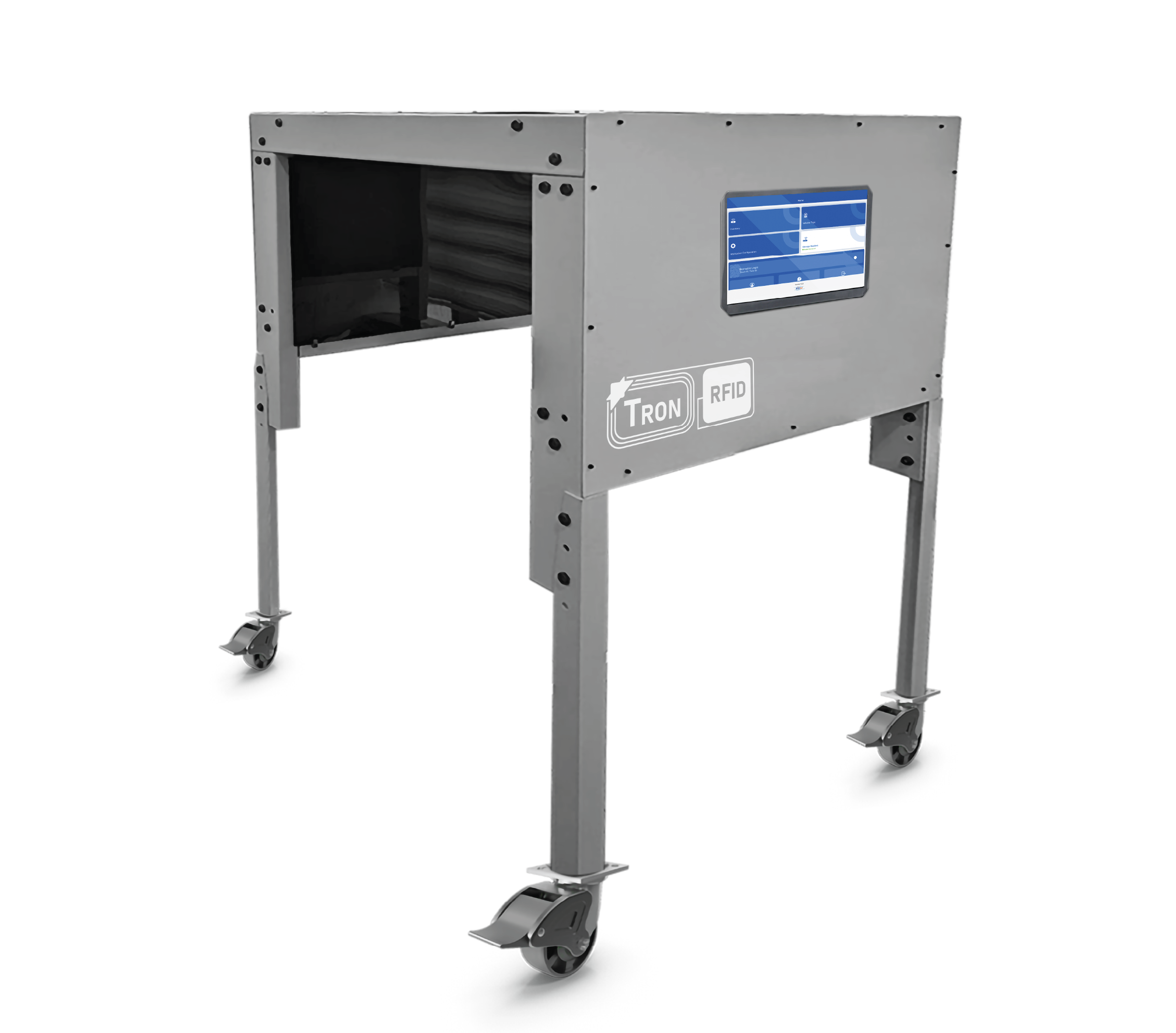

RFID Hardware

RFID4U offers a wide range of hardware, including fixed RFID readers, handheld devices, TronRFID portals, TronRFID tunnels, and antennas These tools enable seamless data capture, improve warehouse automation, and ensure smooth tracking of inventory across inbound, outbound, and storage operations.

RFID Tags & Labels

We provide versatile RFID tags and labels designed for warehouse needs, including pallet tags, item-level RFID labels, and durable on-metal tags. These solutions help improve asset identification, streamline inventory management, and enhance tracking accuracy even in challenging environments.

RFID Software

Our TagMatiks AT is a powerful, cloud-based RFID software for a warehouse. It provides real-time inventory tracking, detailed reporting, and seamless integration with existing WMS/ERP systems, helping warehouses achieve visibility, efficiency, and data-driven decision-making.

Why Choose RFID4U?

With decades of proven expertise, RFID4U delivers scalable and customizable RFID solutions that grow with your business. Our systems integrate seamlessly with existing ERP/WMS platforms, while dedicated support and training ensure your team maximizes ROI and achieves long-term warehouse

Ready to Transform Your Warehouse?

With RFID, you can eliminate inefficiencies, gain real-time visibility, and optimize every stage of warehouse operations.

Frequently Asked Questions (FAQs)

-

How does RFID in warehouses differ from traditional barcodes?

RFID eliminates the need for line-of-sight scanning, unlike barcodes. Multiple items can be read simultaneously, enabling faster inventory counts, improved accuracy, and real-time tracking of stock and assets.

-

Can RFID integrate with my existing Warehouse Management System (WMS) or ERP?

Yes, RFID solutions like TagMatiks AT integrate seamlessly with most WMS and ERP platforms, ensuring smooth adoption without disrupting your existing processes.

-

Can RFID integrate with my existing Warehouse Management System (WMS) or ERP?

Yes, RFID solutions like TagMatiks AT integrate seamlessly with most WMS and ERP platforms, ensuring smooth adoption without disrupting your existing processes.

-

What types of RFID tags are used in warehousing?

Warehouses typically use pallet tags, item-level RFID labels, and on-metal tags for durable assets. The choice depends on the environment, material type, and tracking requirements.

-

What is the ROI timeline for implementing RFID in warehouses?

It depends on operation size and complexity. Savings come from reduced labor, fewer errors, better inventory control, and improved efficiency.

-

How does RFID help in logistics and asset tracking?

In logistics, RFID automates inbound and outbound processes, ensuring faster receiving and accurate shipments. For asset tracking, RFID monitors warehouse equipment, pallets, and containers, reducing losses and improving utilization.