Description

TronRFID Smart Cabinet for Industrial Tool Management

Managing tools in industries like manufacturing, aerospace, automotive, and heavy engineering is often more complex than it seems. Tools are expensive, specialized, and critical to production. Yet, many companies still rely on manual sign-out sheets, paper logs, or basic lock-and-key storage, which leads to misplaced tools, lost time searching, and even safety risks when tools are unaccounted for.

The TronRFID Smart Cabinet for Industrial Tool Management is designed to solve these challenges with a modern, automated, and intelligent storage solution. Using RFID technology, the cabinet provides real-time visibility, secure access control, and data-driven insights to keep tools available, traceable, and well-maintained.

Unlike traditional cabinets, this isn’t just storage—it’s a complete tool management system that improves efficiency, prevents losses, and extends the life of your tools.

Key Features & Benefits

1. Automated Tool Tracking with UHF RFID

- Every tool is tagged with a passive UHF RFID tag (a small, durable tag that requires no battery).

- Built-in RFID readers automatically detect which tools are inside or removed—no manual scanning or checklists required.

- Staff can instantly see whether a tool is available, in use, or missing, eliminating wasted time searching or guessing.

- This system reduces human error and ensures accurate, real-time inventory tracking 24/7.

2. Robust Access Control & Accountability

- Only authorized personnel can open the cabinet, using RFID badges, PIN codes, or biometric authentication (like fingerprint or face ID).

- Every action—opening the cabinet, removing a tool, or returning it—is logged with user details and timestamps.

- This ensures full accountability and discourages tool theft or misuse.

- Managers can instantly trace who last used a tool, reducing disputes and improving responsibility.

Example: If a specialized drill is missing, the system shows exactly who last checked it out and when.

3. Operational Efficiency Gains

- Cuts down the time workers spend signing tools in/out or searching for them.

- Provides instant reports for audits, compliance checks, and productivity analysis.

- Cross-cabinet coordination: If you have multiple cabinets across departments or sites, they communicate to prevent duplicate withdrawals and help locate tools quickly.

- Results in reduced downtime, faster workflows, and better project scheduling.

4. Industrial-Grade Cabinet Design

- Built for tough industrial environments, from noisy shop floors to dusty warehouses.

- Strong, rugged construction with lockable doors ensures both security and durability.

- Resistant to dust, vibration, and heavy-duty usage, making it suitable for factories, energy plants, and field operations.

Use Cases in Industry

The TronRFID Smart Cabinet is highly adaptable and can be implemented across a wide range of industrial sectors where tool availability, accountability, and security are critical.

Manufacturing & Assembly Lines: Manufacturing & Assembly Lines benefit greatly from the smart cabinet, as it keeps essential tools readily available and reduces downtime caused by misplaced or missing equipment. The system also supports lean production practices by enabling quick and efficient tool changeovers, ensuring uninterrupted workflows.

Aerospace & Defense: In the Aerospace & Defense industry, the cabinet plays a vital role in tracking highly specialized and calibrated instruments used in aircraft assembly and maintenance. With its detailed access logs and secure storage, it ensures compliance with strict industry standards and safety regulations while safeguarding mission-critical tools.

Automotive Workshops & Service Centers: For Automotive Workshops & Service Centers, the smart cabinet eliminates confusion in tool sharing by automatically recording every transaction. This helps mechanics easily locate and return tools while reducing the chances of loss or misplacement in busy, high-traffic environments.

Oil, Gas & Energy Sector: In the Oil, Gas & Energy Sector, the cabinet provides reliable tracking for portable tools that are frequently used in remote or hazardous locations. By ensuring that all tools are checked out and returned properly, it prevents costly losses and enhances accountability during fieldwork.

|

HSN Code |

94032090 |

|

COO |

India |

Why Choose TronRFID Smart Cabinet?

- Saves Time: Workers spend less time searching for tools and more time being productive.

- Reduces Losses: Prevents theft, misplacement, and accidental hoarding of tools.

- Improves Safety & Compliance: Ensures critical tools are accounted for and properly maintained.

- Data-Driven Decisions: Provides managers with insights on usage trends, replacements, and purchasing needs.

Product Summary

The TronRFID Smart Cabinet is a secure, RFID-enabled storage solution for industrial tool management. It provides real-time visibility, automated tracking, and controlled access to tools, reducing loss, misplacement, and downtime. With rugged design and smart software integration, it ensures accountability, improves workflow efficiency, and supports compliance in demanding industrial environments.

Frequently Asked Questions

What is the TronRFID Smart Cabinet for Industrial Tool Management?

The TronRFID Smart Cabinet is an intelligent storage and tracking solution that uses RFID technology to manage industrial tools. It provides real-time visibility, secure access control, and predictive insights to ensure tools are always available, traceable, and well-maintained.

How does the smart cabinet track tools?

Each tool is fitted with a passive UHF RFID tag. The cabinet’s built-in RFID readers automatically detect when a tool is stored or removed, providing instant updates without manual scanning or checklists.

Who can access the cabinet?

Only authorized personnel can access the cabinet using RFID cards, PIN codes, or biometric authentication such as fingerprint or face recognition. Every action is logged for complete accountability.

Can the cabinet prevent tool theft or misplacement?

Yes. Since every access and tool transaction is recorded, managers can quickly trace who used a tool last. This deters theft, prevents accidental hoarding, and reduces disputes about tool usage.

Is the cabinet suitable for heavy industrial environments?

Absolutely. The cabinet is built with rugged, powder-coated steel, lockable doors, and dust- and vibration-resistant features, making it suitable for factories, energy plants, aerospace facilities, and field operations.

Can it integrate with existing ERP or business logic?

Yes. The cabinet can be integrated using TagMatiks Middleware (TagMatiks Core) with ERP, WMS, and other enterprise platforms for seamless workflow management.

Is there any software available for this smart cabinet?

We don’t offer pre-built software for this smart cabinet at the moment. However, our team can design and develop customized software tailored to your requirements. For more details, please contact us at +91 9205947800 .

How does it help improve operational efficiency?

By automating check-in/check-out, reducing search time, and providing real-time reports, the cabinet minimizes downtime, speeds up workflows, and helps with accurate audits and compliance.

What industries can benefit most from this smart cabinet?

Industries like manufacturing, aerospace & defense, automotive workshops, and oil, gas & energy sectors benefit significantly due to the need for tool accountability, availability, and compliance.

Get the Support You Need

Have questions about our RFID products or need help with installation? Our dedicated Customer Success team is here ( +91 9205947800 ) to ensure you have a smooth experience from start to finish. We're ready to assist with any technical issues, product inquiries, or installation guidance you may need.

Product Summary

The TronRFID Smart Cabinet for Industrial Tool Management is a rugged, automated storage solution. It uses UHF RFID to track and manage expensive and critical tools in real-time, eliminating manual systems. The cabinet features secure access (RFID, PIN, or biometrics) and AI-powered insights for tool demand forecasting and maintenance scheduling, improving operational efficiency and accountability.

Additional Information

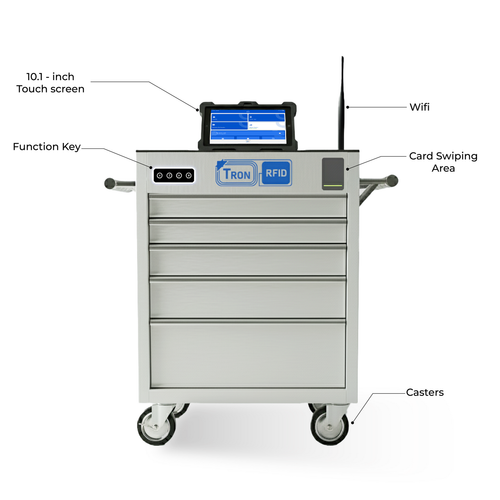

Physical Characteristics: |

(920 x 460 x 1259 mm), (36.22 x 18.11 x 49.56 inch) (L x W x H). Customizable based on application and operational requirements |

Mobility: |

Caster wheels with adjustable feet |

Weight: |

~60 kg |

Locking Mechanism: |

Electromagnetic lock with access logging |

Material: |

Powder-coated steel |

RFID Reader Compatibility: |

Impinj R700, Zebra FX7500 |

Frequency Range: |

865-868 MHz (ETSI), 902-928 MHz (FCC) |

Protocols Supported: |

EPC Gen2v2, ISO 18000-6C |

Read Accuracy: |

≥99.9% |

Read Speed: |

Up to 1300 tags/sec |

Tag Filtering: |

RSSI-based, EPC whitelist/blacklist |

Touch Screen: |

15" capacitive, 1920x1080 resolution |

Authentication: |

RFID card (standard), face/fingerprint (optional) |

Alarm System: |

Alerts for unauthorized access |

Communication: |

Ethernet, Wi-Fi, 4G |

Software Platform: |

Windows / Android OS |

Integration Interfaces: |

RESTful API, MQTT |

ERP/WMS Integration: |

Supported via middleware |

Humidity Range: |

10% RH to 90% RH |

Download Data Sheet: |

https://rfid4ustore.in/content/TronRFID%20Smart%20Cabinet%20for%20Industrial%20Tool%20Management.pdf |