Description

TronRFID Tunnel

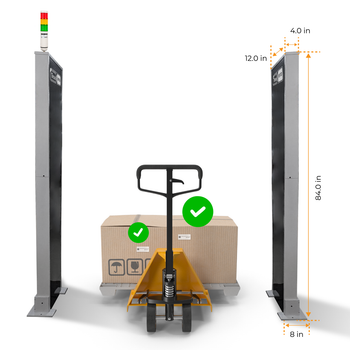

RFID tunnel that automatically identifies and tracks items as they move through a conveyor belt.

TronRFID tunnels are mounted along conveyors to monitor tagged items as they move through production or packaging lines, ensuring accurate tracking of goods in fast-moving operations.

The TronRFID Tunnel is designed for adaptability, featuring adjustable height to suit application needs. Its structural flexibility allows it to accommodate different conveyor widths with minor structural modifications. The specialized antenna and thoughtful design maximize reading inside and minimize reading outside of the tunnel.

Advanced AI-driven Features

|

Our upcoming TagMatiks software release will incorporate advanced AI-driven features to enhance RFID tunnel performance and reliability. Key capabilities will include: Reduction of False Reads / Ghost Tags through intelligent filtering and zone-aware algorithms These enhancements will deliver smarter automation, improved data integrity, and greater operational efficiency across deployments. |

|

Industry Applications

TronRFID Tunnel is ideal for sectors that demand precision, speed, and scalability:

Warehousing: Automated receiving and dispatch with accurate inventory reconciliation

Manufacturing: Real-time tracking through production stages for quality control

Logistics & 3PL: Streamlined sorting and routing of goods across distribution centers

Retail & E-commerce: Bulk item identification for order fulfillment and returns processing

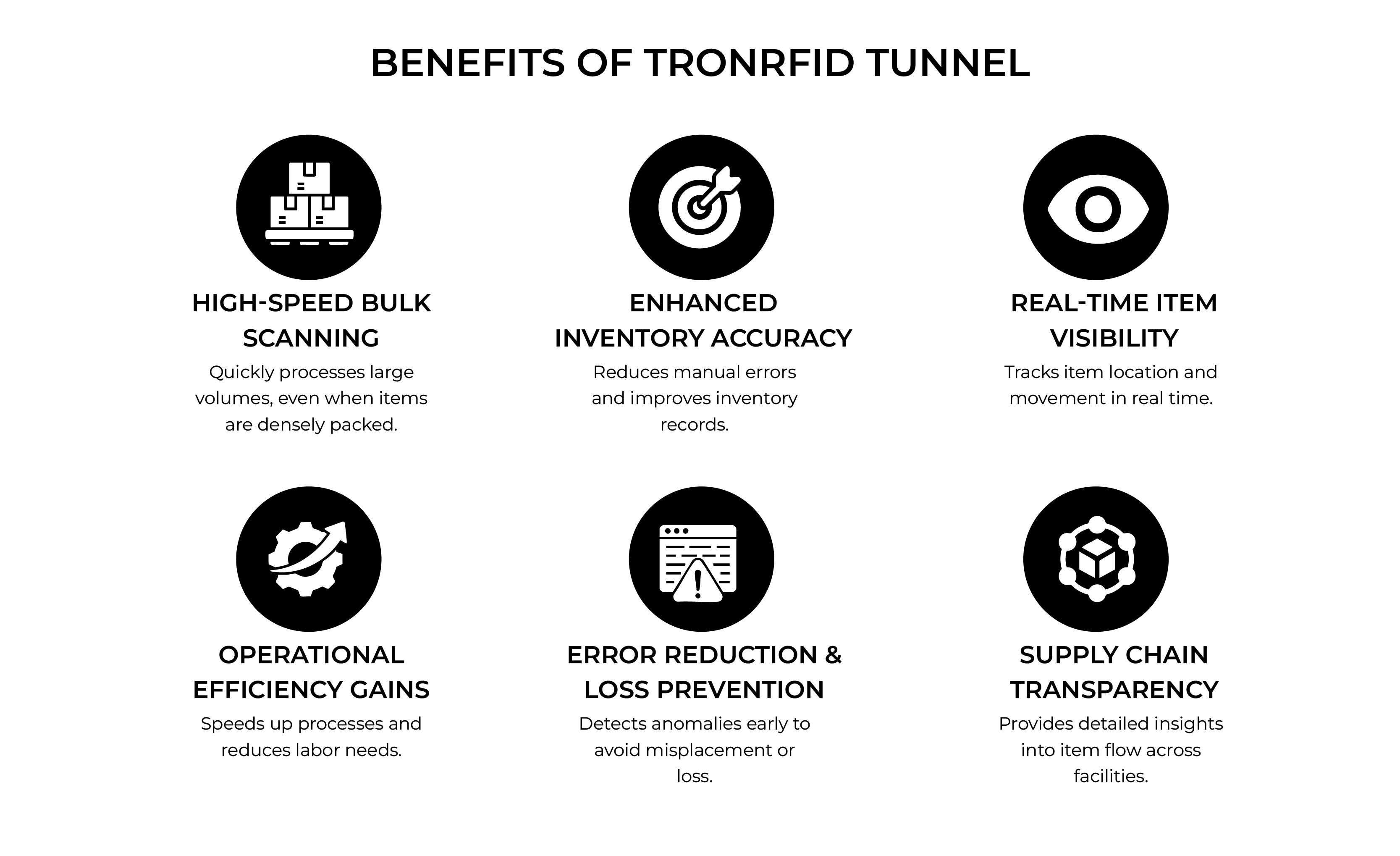

Business Benefits

Deploying the TronRFID Tunnel unlocks measurable operational advantages:

High-Speed Bulk Scanning Efficiently processes large volumes of items without bottlenecks, even when products are stacked or densely packed.

Enhanced Inventory Accuracy Reduces manual counting errors and ensures reliable inventory records through automated tracking.

Real-Time Item Visibility Provides continuous monitoring of item movement and location, enabling proactive decision-making.

Operational Efficiency Gains Automates identification tasks, reduces labor dependency, and accelerates throughput.

Error Reduction & Loss Prevention Early detection of anomalies helps prevent misplaced items and production errors.

Supply Chain Transparency Offers granular insights into item flow across facilities, supporting better planning and responsiveness.

The TronRFID Tunnel is more than just an RFID tunnel—it’s a strategic asset for businesses seeking to modernize their material handling and supply chain operations. With its intelligent design, flexible configuration, and high-performance RFID capabilities, it empowers organizations to achieve precision, scalability, and efficiency in even the most demanding environments

| Reader Options | Technical Overview |

|

Zebra FX7500 |

|

|

Impinj R700

|

|

Add-ons

| Add-on | Purpose |

|---|---|

|

Stack Light

|

A stack light (also called a signal tower or indicator light) is a visual alert device mounted on a portal to show the current status using colored lights. For example:

|

|

Barcode Scanner

|

A barcode scanner enhances the functionality and reliability of the RFID tunnel in hybrid environments where not all items are RFID-tagged. Barcode data can be cross-referenced with RFID reads to improve data validation. Adding a scanner also ensures compatibility with older systems while transitioning to full RFID automation |

|

Photoelectric Sensor

|

Adding a photoelectric sensor to an RFID tunnel significantly enhances its intelligence and responsiveness. Detects item presence, triggering RFID read only when needed, reducing false reads and improving accuracy. |

|

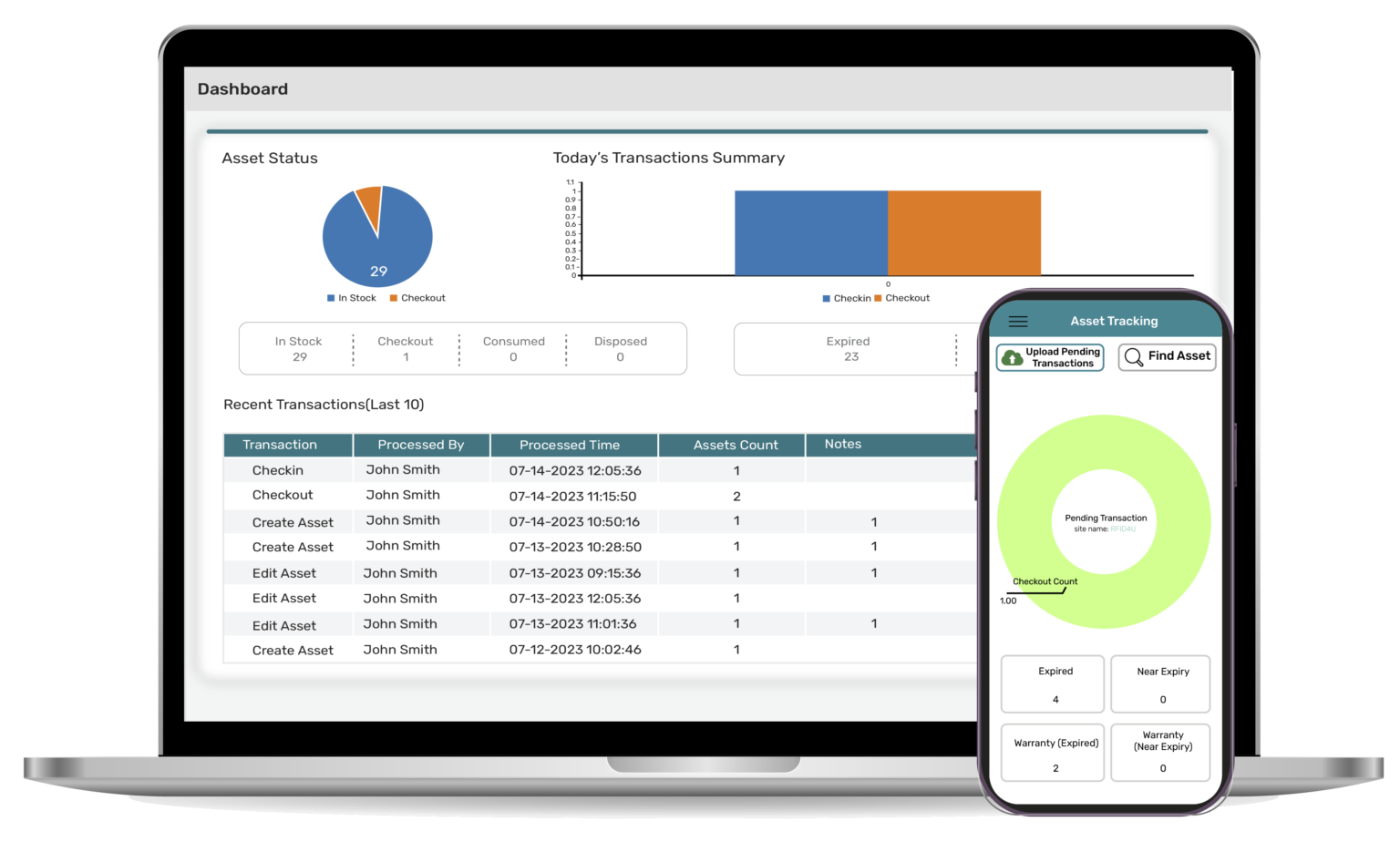

UI Interface

|

The User Interface (UI) provides real-time visibility into read events, tag counts, and item movement, allowing operators to quickly spot inconsistencies such as missed or duplicate scans. It also displays system health, antenna status, and reader connectivity, which helps minimize downtime by enabling rapid fault identification. The UI allows users to monitor throughput, scan success rates, and inventory movement over time. Logs can be exported or integrated with ERP/WMS systems for automated reporting. Role-based access ensures that only authorized personnel can modify settings. |

Ordering Information

| Description | SKU | Price in INR | Price in USD |

| TronRFID Tunnel | TRS210080 | ₹345,888.00 | $3,952.00 |

| Zebra FX7500 RFID Reader - 4 Ports | FX7500-42325A50-WR | ₹87,396.00 | $1,016 |

| Impinj R700 RAIN RFID Reader | IPJ-R700-241 | ₹115,000.00 | $1,337 |

Accessories

| Description | SKU | Price in INR | Price in USD |

| Stack Light GPIO Kit for Zebra FX7500 RFID Reader - 4 Ports | TRS210980 | ₹42,000.00 | $488 |

| Stack Light GPIO Kit for Impinj R700 RAIN RFID Reader | TRS211080 | ₹42,000.00 | $488 |

| Photoelectric Sensor GPIO Kit for Zebra FX7500 RFID Reader - 4 Ports | TRS211180 | ₹42,000.00 | $488 |

| Photoelectric Sensor GPIO Kit for Impinj R700 RAIN RFID Reader | TRS211280 | ₹42,000.00 | $488 |

| HSN Code | 84716090 |

| COO | India |

Key Features & Technical Advantages

Seamless Integration & Operational Versatility

TronRFID Tunnels are designed for effortless integration into diverse industrial workflows, offering exceptional performance in dynamic environments:

- Strategic Mounting for Continuous Monitoring Positioned along conveyor lines, the portal continuously scans RFID-tagged items, ensuring accurate tracking from inbound raw materials to outbound finished goods. This real-time data stream supports inventory accuracy, quality assurance, and loss prevention.

- Adjustable Height Mechanism The portal’s vertical adjustability allows precise positioning above conveyors of varying heights, ensuring optimal read angles and consistent tag detection across different product profiles.

- Flexible Width Accommodation Engineered with modular structural components, TronRFID portals can be adapted to fit a wide range of conveyor widths with minimal customization. This reduces installation complexity and supports rapid deployment in existing facilities.

Optimized RFID Read Performance

- Specialized Antenna Architecture TronRFID portals incorporate high-performance antennas specifically tuned for tunnel environments. These antennas deliver focused, high-accuracy reads even in dense tag populations or high-speed operations.

- Shielded Read Zone for Data Integrity The portal’s enclosure and antenna layout are designed to suppress external interference, creating a tightly controlled read zone. This minimizes stray reads from nearby items and ensures that only in-tunnel products are captured—critical for maintaining clean, actionable data.

Frequently Asked Questions

What is a TronRFID Tunnel RFID Portal used for?

The TronRFID Tunnel is used to automatically identify and track RFID-tagged items as they pass through conveyor belts in warehouses, manufacturing, and packaging lines—ensuring high-speed, accurate inventory management.

What types of industries benefit most from using this portal?

Industries such as warehousing, logistics, manufacturing, and supply chain operations benefit significantly due to the need for high-speed, accurate tracking of goods.

Is the tunnel customizable to different conveyor sizes?

Yes, the TronRFID Tunnel is custom-built to fit operational needs. Its adjustable height and flexible frame allow it to be modified for different conveyor widths and tunnel sizes.

What types of items can this RFID portal track?

It can track any RFID-tagged items, including boxes, containers, packages, and individual products—ideal for high-volume operations where speed and accuracy are critical.

What RFID readers are compatible with this portal?

The portal is designed to support multiple RFID reader models. Compatibility can be tailored to the customer's requirements during deployment.

Can the portal operate in extreme environments?

Yes, the portal operates in a temperature range of -20°C to +60°C, making it suitable for most industrial environments.

How does the portal help improve operational efficiency?

It automates scanning and tracking processes, reduces reliance on manual entry, improves inventory accuracy, and minimizes labor costs—especially in fast-paced production or packaging lines.

What is the warranty offered?

The TronRFID Tunnel comes with a one-year warranty against manufacturing defects from the date of invoice.

Does it support bulk scanning of stacked items?

Yes, the portal is optimized for high-speed bulk identification, making it capable of reading stacked or closely packed RFID-tagged items efficiently.

Does it support real-time alerts or reporting?

Yes, when integrated with suitable RFID middleware or enterprise software, it can provide real-time alerts, dashboards, and analytics on item movement and inventory status.

How difficult is installation and setup?

Installation is straightforward for most environments. TronRFID offers technical support and guidance to ensure proper setup and configuration tailored to your workflow.

Get the Support You Need

Have questions about our RFID products or need help with installation? Our dedicated Customer Success team is here (+919205947800) to ensure you have a smooth experience from start to finish. We're ready to assist with any technical issues, product inquiries, or installation guidance you may need.

Product Summary

The TronRFID Tunnel is a rugged, tunnel-style RFID system designed to automatically identify and track tagged items on conveyor belts—ideal for high-speed environments like warehouses, manufacturing lines, logistics, and e-commerce. It features a customizable, height-adjustable frame with tailored antennas that ensure precise reads inside the tunnel while minimizing outside interference. The portal supports multiple reader models, handles stacked or bulk items efficiently, operates in a wide temperature range, and delivers real-time data when integrated with enterprise software—backed by a one-year warranty.

Additional Information

Physical Characteristics: |

Length: 3 feet ( 36.0 in ), Width: 3 feet ( 36.0 in ), Height: 4.5 feet ( 54.0 in ) (Size can be Customized as per requirement) |

Weight: |

75Kg |

Size of Tunnel Opening: |

2.5 feet/30.0 in ( can be customized as per requirement) |

Recommended distance between objects: |

1 Feet / 12 Inch |

Construction: |

Powder Coated Steel |

RFID Reader Compatibility: |

Impinj R700, Zebra FX7500 |

Max. ERP: |

2W |

Temp. Range: |

-20° C to +60° C |

Polarization: |

Circular Polarization |

Gain: |

5dbi |

Antenna Count: |

2 |

Vertical beamwidth: |

35° |

Horizontal Beamwidth: |

103° |

RF Cables: |

Low-loss cables, included |

Cable Type: |

TNC to SMA |

Power Sources: |

POE, POE+ |

Download data sheet: |

https://rfid4ustore.in/content/TronRFID%20Tunnel%20Portals.pdf |