RFID Tag Data Storage Capacity and How It Works

Introduction

Radio Frequency Identification (RFID) technology has revolutionized the way we track, identify, and manage items across a wide range of industries—from retail to healthcare and logistics. At the core of this system are RFID tags, which store data that can be accessed wirelessly via RFID readers.

While RFID technology is often associated with fast scanning and automation, one of its less-discussed but crucial aspects is data storage capacity. Understanding how much and what kind of data RFID tags can hold is essential for selecting the right tag for the job.

In this blog, we’ll explore the structure of RFID tag memory, how data is stored and accessed, and how storage capacity influences real-world applications.

Understanding RFID Tag Basics

An RFID tag is a small electronic device that uses radio waves to transmit data to an RFID reader. It typically consists of a microchip (which stores data) and an antenna (which enables communication). RFID tags can be attached to or embedded in objects, enabling automatic identification without direct line of sight.

Types of RFID Tags

Passive RFID Tags: Passive RFID Tags operate without an internal power source, drawing energy from the RFID reader’s signal. They are cost-effective and widely used in applications like inventory control, retail management, and supply chain tracking.

Common Use Cases

- Inventory management in retail

- Vehicle and tire tracking

- Hospital equipment monitoring

- Tool tracking in construction

- Access control in secure facilities

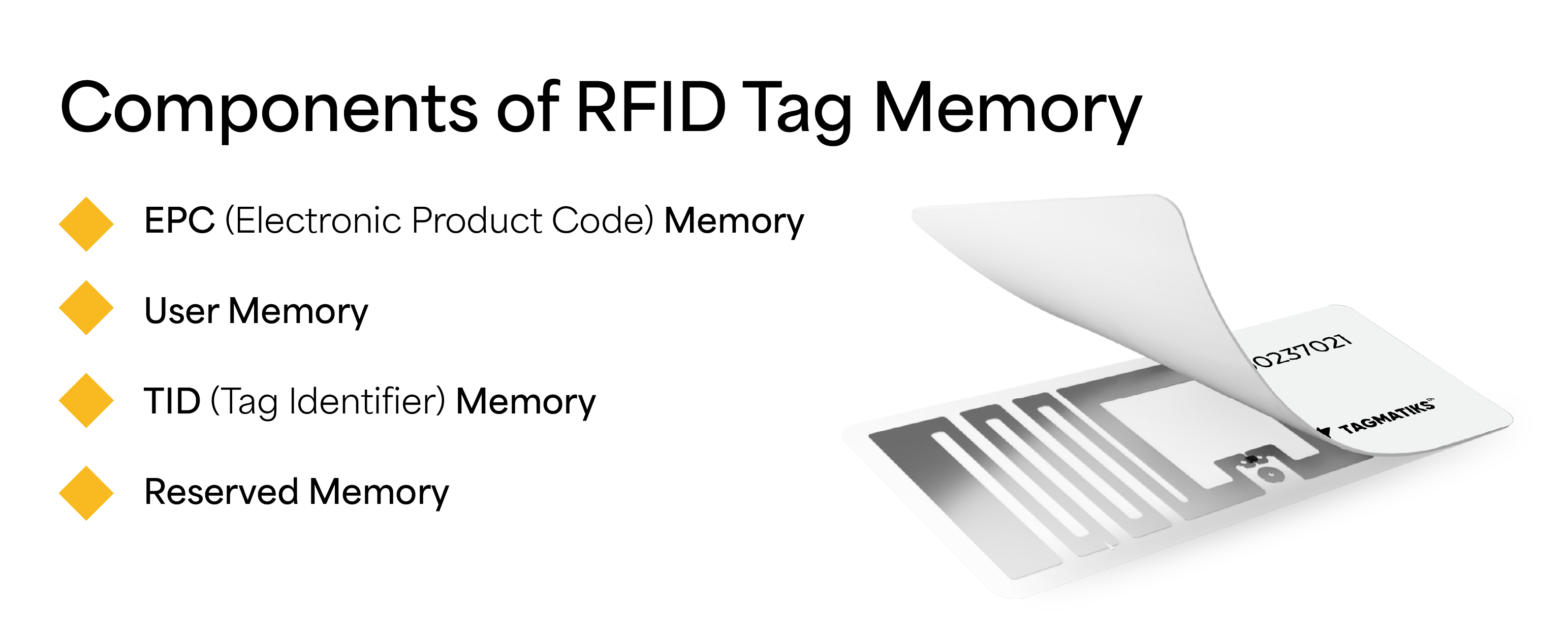

Components of UHF RFID Tag Memory

RFID tag memory is divided into several memory banks, each with a specific role:

1. EPC (Electronic Product Code) Memory

This memory bank holds the unique identifier for the item. Typically ranging from 96 to 128 bits, the EPC enables systems to differentiate between millions or billions of items. In certain cases, like automotive, it may be up to 256 bits.

2. User Memory

Optional and available on some tags, this memory can store additional data such as manufacturing dates, maintenance logs, batch numbers, or sensor readings. Capacity varies from a few bytes to several kilobytes.

3. TID (Tag Identifier) Memory

The TID is a factory-programmed, read-only section that contains a unique identifier for the tag itself. It's useful for authentication and tag serialization.

4. Reserved Memory

This memory bank stores access and kill passwords, which provide security control. The access password is used to lock/unlock memory, while the kill password can permanently disable a tag.

|

Memory Bank |

Purpose |

Editable |

|

EPC |

Stores the item identification code |

Yes (by user) |

|

User |

Stores application-specific data |

Yes (if supported) |

|

TID |

Unique tag identifier |

No (read-only) |

|

Reserved |

Passwords for access/security |

Yes (controlled) |

Typical Capacities

Low-memory tags: ~96–128 bits in EPC memory

These tags store basic item identifiers, ideal for retail and inventory tracking where minimal data is needed. They're optimized for fast scanning and cost-effective bulk tagging.

Medium-memory tags: ~512 bits to 2 KB

Used in supply chain and manufacturing, these tags hold additional data like batch numbers, production dates, or compliance info, allowing more detailed tracking without needing database lookups.

High-memory tags: up to 8 KB or more

These tags store large datasets such as sensor readings, maintenance logs, or location history—commonly used in cold chain, pharmaceuticals, or industrial equipment tracking.

Examples

EPC Class 1 Gen 2 Tags: Most common tags with 96-bit EPC and optional user memory

Widely adopted across industries, these tags are cost-efficient and ideal for fast identification tasks. Optional user memory can be used for storing application-specific details like lot codes.

Sensor-Enabled Tags: Can store logs from temperature or humidity sensors in memory banks with capacities from 1–8 KB

Equipped with onboard sensors, these tags monitor environmental conditions and store time-stamped logs directly in memory, ensuring traceability for perishable goods, vaccines, or sensitive equipment.

Low vs High Memory Tags: A Comparison

|

Use Case |

Memory Needed |

Tag Type |

|

Retail Inventory |

Low |

EPC Gen 2 (96-bit) |

|

Tool Tracking in Industry |

Medium |

EPC + User Memory |

|

Cold Chain Temperature Log |

High |

Sensor Tag (4–8 KB) |

How Data is Stored and Accessed

Read/Write Capabilities

RFID tags offer different read/write capabilities: Read-Only tags are factory-programmed and unchangeable, WORM tags can be written once and then locked, while Read/Write tags support multiple updates, ideal for dynamic data like status or location.

Reader Interaction

RFID readers interact with tags using standardized communication protocols like ISO 18000-6C for UHF tags. Readers send commands to access specific memory banks, and the tag responds by transmitting the requested data wirelessly over radio frequency signals.

Addressing and Memory Blocks

RFID tag memory is divided into addressable blocks or “words” that the reader can target for data operations. For example, EPC memory may be segmented into 16-bit words, allowing specific portions to be read, written, or locked without affecting the rest.

Security Features

RFID tags include security features such as access passwords to restrict unauthorized data access, kill passwords to permanently disable tags after use, and lock bits to secure specific memory sections, ensuring data remains unchanged and protected during handling.

Factors Affecting RFID Storage Use

Application-Specific Requirements

The required memory size of an RFID tag depends on the type of data being stored. For instance, if you only need to identify a product with a unique ID, a low-memory EPC tag (96–128 bits) is sufficient. However, if your application involves storing manufacturing data, sensor logs, or maintenance records, then high-memory tags with user memory up to several kilobytes are better suited for the job—such as in cold chain monitoring or industrial equipment tracking.

Limitations in Passive Tags

Passive RFID tags draw power from the reader’s signal, which limits their memory capacity, range, and speed. As memory increases, read range often decreases, and performance can be affected.

Trade-Offs

More memory = larger chip = higher cost

High-memory tags require larger chips, which increases manufacturing and unit costs.

More memory = longer read/write time

Reading or writing large amounts of data takes more time, slowing down operations.

Larger memory = shorter read distance (in passive tags)

Increased memory can reduce signal strength, resulting in shorter read ranges for passive tags.

Use Cases Based on Data Storage Needs

Retail (Low Memory)

In retail, RFID tags with low memory, typically just EPC, are ideal for fast item identification, bulk inventory tracking, and theft prevention. These tags are cost-effective and support high-speed scanning during stock audits or checkout processes.

Manufacturing and Logistics (Medium Memory)

Medium-memory tags are used to store batch numbers, production dates, or regulatory data. These tags support traceability across supply chains, enabling quality control, shipment verification, and compliance tracking throughout the manufacturing and distribution lifecycle.

Healthcare & Cold Chain (High Memory)

High-memory RFID tags in healthcare and cold chain logistics can log time-stamped sensor data like temperature or shock. This ensures full visibility, supports regulatory compliance, and helps maintain safety for sensitive products like vaccines or perishables.

Asset Tracking (Variable Memory)

In asset tracking, RFID tags use variable memory to store data such as maintenance schedules, calibration history, and assigned users. This enables quick access to detailed records directly from the asset without relying solely on backend databases.

Automotive (Medium to High Memory)

In the automotive industry, RFID tags are used to store VINs, part IDs, and manufacturing details, typically requiring memory capacities of up to 256 bits or more. These tags enable accurate component tracking, quality control, and full vehicle traceability from assembly to after-sales service.

Conclusion

RFID tags may seem simple on the surface, but their data storage capacity plays a critical role in how effectively they serve different applications. From basic product identification to advanced sensor data logging, RFID memory options are as varied as their use cases.

When selecting an RFID tag, it’s vital to balance memory requirements with performance, cost, and intended application. Understanding the structure of RFID tag memory—EPC, TID, user memory, and security layers—helps ensure you choose the right tag for the job.

Need help selecting the right RFID tag for your application? Reach out to RFID experts or consult with solution providers who can guide you based on your use case.

Recent Posts

-

Work-in-Progress Tracking with RFID in Manufacturing

Introduction In manufacturing, Work-in-Progress (WIP) refers to items that are in various stages of …Feb 20th 2026 -

Beginner’s Guide to RFID Technology – What It Is & How It Works

Introduction Have you ever noticed how warehouses can track hundreds of boxes moving in and out with …Feb 16th 2026 -

EPC in RFID Tags Explained: Boost Tracking Accuracy & Efficiency

Introduction Radio Frequency Identification (RFID) has become a cornerstone of modern industries, en …Feb 13th 2026