Description

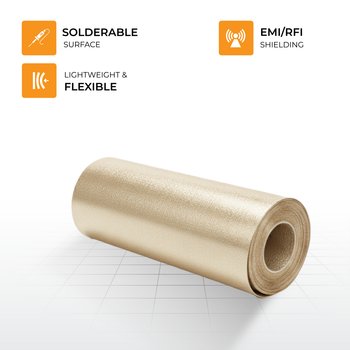

TronRFID Nickel Copper Conductive Fabric

TronRFID nickel-copper conductive fabric is engineered from a polyester-based substrate, enhanced through advanced metallization techniques. Initially, a layer of nickel is deposited onto the polyester via chemical or physical transfer methods. This is followed by the application of a high-conductivity copper layer, which is then sealed with an anti-oxidation nickel coating to ensure long-term durability and corrosion resistance.

The synergistic combination of copper and nickel delivers superior electrical conductivity and outstanding electromagnetic shielding performance. With a surface resistance of less than 0.05 ohm per 10 cm, this fabric achieves shielding effectiveness exceeding 70 dB, making it ideal for high-performance EMI/RFI protection.

Due to its metal-coated structure, the fabric is not suitable for washing, as exposure to moisture or abrasion may compromise the integrity of the conductive layers. It is best utilized in non-washable applications such as

- Internal lining for shielding enclosures

- Electromagnetic shielding curtains

- Anti-static garments and surfaces

This fabric offers a reliable solution for environments requiring robust EMI shielding without sacrificing flexibility or ease of integration.

Frequently Asked Questions

What is the TronRFID Nickel Copper Conductive Fabric?

It is a polyester-based fabric coated with nickel and copper layers, providing excellent conductivity and EMI/RFI shielding performance.

How effective is this fabric in shielding electromagnetic interference?

The fabric achieves shielding effectiveness up to 75 dB with surface resistance of less than 0.05 ohm per 10 cm, making it ideal for high-performance EMI/RF shielding.

What are the main applications of this conductive fabric?

It is used in shielding enclosures, electromagnetic curtains, RFID blocking, anti-static garments, and electronic device protection.

Can the fabric be washed?

No. Due to its metal-coated structure, the fabric is not suitable for washing, as moisture or abrasion may damage the conductive layers.

What are the available color options?

The fabric is available in silver grey and black, offering flexibility for different industrial and design needs.

What is the standard roll width and weight?

Each roll comes with a width of 108 cm and weighs approximately 80 g/m², making it lightweight and easy to handle.

How does the nickel coating improve durability?

The outer anti-oxidation nickel coating protects the copper layer from corrosion, ensuring long-term stability and performance.

Is this fabric suitable for RFID shielding?

Yes. It provides 100% RFID blocking efficiency, making it highly effective in secure data environments.

What type of weave structure does it use?

The fabric is made with a plain weave structure, ensuring flexibility and consistent shielding performance.

How is the TronRFID Nickel Copper Conductive Fabric supplied?

It is supplied in rolls, making it convenient for large-scale industrial, research, and manufacturing applications.

Product Summary

The TronRFID Nickel Copper Conductive Fabric is a high-performance polyester-based material providing robust EMI/RFI shielding (75 dB) and 100% RFID blocking. It features a nickel-copper coating for superior conductivity and long-term durability. This flexible fabric is designed for non-washable applications such as lining shielding enclosures, electromagnetic curtains, and anti-static surfaces.

Additional Information

Material: |

Polyester-based fabric with nickel and copper coating |

Roll Width: |

108 cm |

Weight: |

80 g/m² |

Color Options: |

Silver grey, Black |

Weave Structure: |

Plain |

Fabric Type: |

Conductive fabric, RFID blocking fabric |

Surface Resistance: |

< 0.05 ohm per 10 cm |

Shielding Effectiveness: |

75 dB (High-performance EMI/RF shielding) |

Shielding Efficiency: |

100% (Ideal for RFID and RF isolation) |

Key Features: |

High conductivity, RFID blocking, RF shielding |

Packaging: |

Supplied in rolls |

Download Data Sheet: |

https://rfid4ustore.in/content/TronRFID%20Nickel%20Copper%20Conductive%20Fabric.pdf |