Best Practices for Installing RFID Readers for Maximum Read Accuracy

Introduction

RFID systems are revolutionizing how businesses track assets, manage inventory, and automate operations. At the core of any RFID system are the readers—the devices responsible for detecting and interpreting signals from RFID tags.

While tags and software are important, the installation and configuration of RFID readers play a critical role in determining the system's effectiveness. Improper placement or setup can lead to missed reads, stray reads, or inconsistent data.

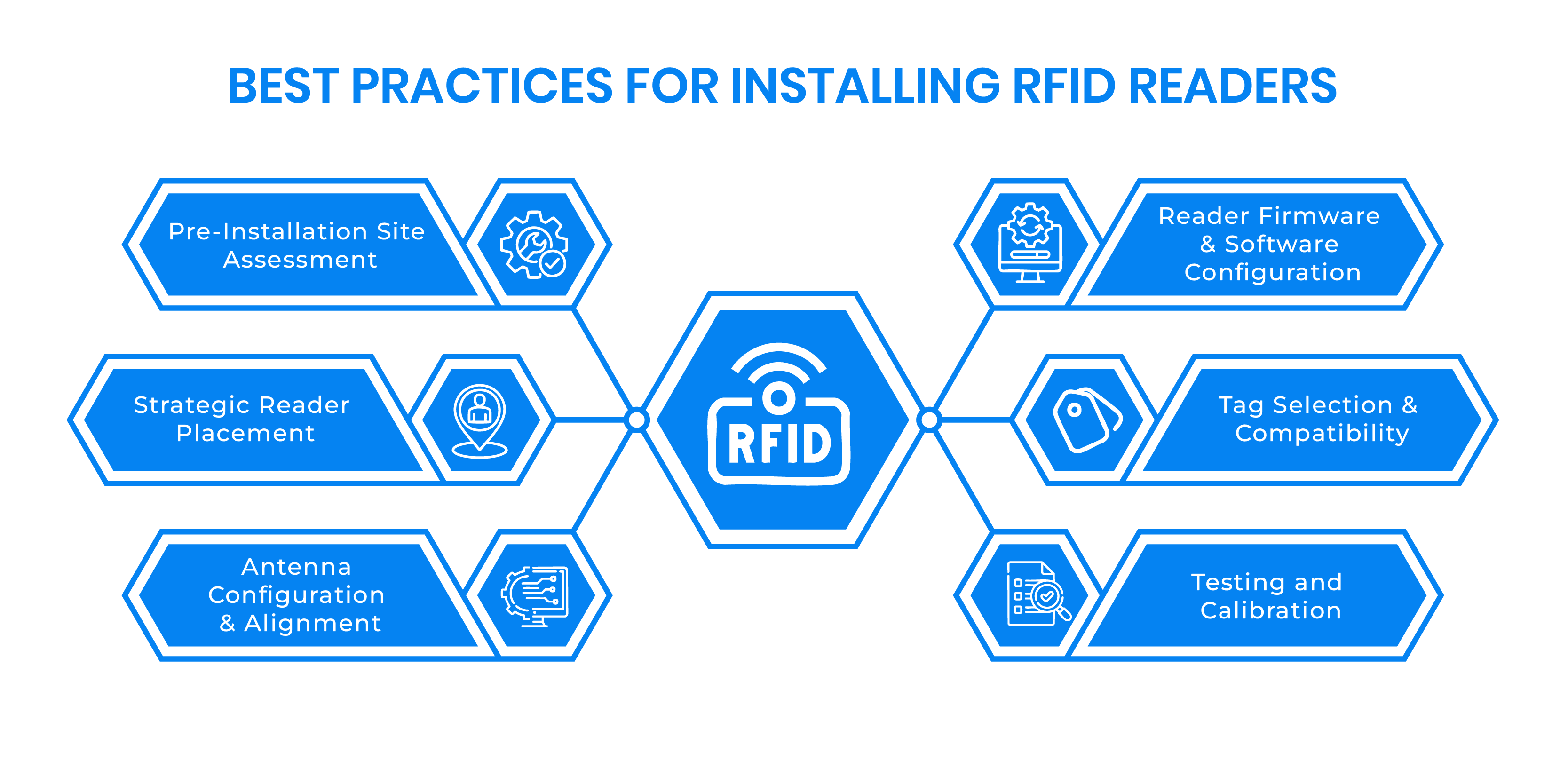

This blog will guide you through the essential best practices for installing RFID readers to achieve the highest possible read accuracy. We'll cover technical setups, environmental considerations, and practical tips to help you maximise the benefits of your RFID investment.

Understanding RFID Reader Types and Their Use Cases

Fixed Reader

Fixed Readers are stationary devices typically mounted at entry/exit points, conveyor belts, or gate portals, offering consistent and automated read zones for hands-free tracking of tagged items. Fixed readers demand precise planning for mounting height, antenna angles, and power supply.

Portable Handheld Readers

Handheld Readers are mobile devices used by staff to scan tags, making them ideal for performing on-the-go inventory counts, locating items, or verifying product information in real time. Handheld readers emphasize ease of use, battery life, and ergonomic design.

Integrated Reader

Integrated Readers are all-in-one devices with built-in antennas and casings, making them plug-and-play solutions that reduce setup complexity and are ideal for quick or semi-permanent installations. They are ideal for overhead mounting for automatic tracking of items through exit and entry gate, crowd management, attendance system, etc.

Reader Modules

Reader Modules are core components without housing or antennas, offering flexibility to design custom solutions integrated into machinery, kiosks, or specialized enclosures.

Key Factors to be considered before deployment

Site Assessment

Before installing RFID readers, conduct a comprehensive site survey to evaluate the physical space, item flow, infrastructure layout, and possible obstructions. This ensures proper planning of read zones and reader placement for accurate tracking.

Map Tag Paths

Understanding how tagged items move throughout the facility—whether on pallets, carts, or conveyors—helps define optimal reader locations. This prevents blind spots and ensures continuous tag detection during movement across critical control points.

Check for Interference

Metal objects, liquids, or overlapping RFID systems can cause signal reflection, absorption, or interference. Identify and mitigate these elements early during installation planning to ensure clean, consistent signal propagation and maximum read accuracy.

Environmental Factors

Temperature extremes, humidity, dust, and electromagnetic (EM) interference can degrade RFID performance. Choose industrial-grade, ruggedized readers and enclosures to withstand these environmental conditions and maintain reliable operation over time.

Tag Density and Orientation

When many tags are present in close proximity, readers may struggle to distinguish between them. Adjust sensitivity settings or apply anti-collision filtering logic to maintain performance in high-density tag environments.

Read Zone Planning

When designing read zones, ensure slight overlaps between adjacent zones to eliminate blind spots. However, avoid excessive coverage, which can result in duplicated reads and data noise, especially in high-volume environments.

Portal, Conveyor, or Overhead Mounting

Select mounting types based on application needs—portal mounts are ideal for doorways, conveyors for moving goods, and overhead readers work best for scanning tall items or vehicles entering secured areas.

Avoiding Reader-to-Reader Interference

To prevent signal clashes between nearby readers, implement time-division multiplexing and stagger their reading schedules. Also, maintain proper spacing to minimize signal overlap and reduce the chance of inconsistent reads.

Antenna Ports

Reader antenna ports decide how many antennas can be connected to a reader. Depending on the read zone and site survey, one can choose 2,4 or 8-port reader. In special use cases like smart shelves, where multiple antennas are required to connect with a single reader, one can use an antenna hub to connect multiple antennas with a single reader.

Type of Antenna

Antenna selection is crucial for readers to work efficiently at the site. Below are some key points to consider for antenna selection to make the readers' work effective.

Selecting the correct antenna is essential for accurate reads. Circularly polarized antennas are ideal when tag orientation is unpredictable, while linearly polarized ones work best when tags are consistently aligned. Always factor in antenna gain and beam width to ensure proper coverage of your target read zone.

Cabling and Connectors

Use high-quality, low-loss coaxial cables to maintain signal integrity between the reader and antennas. Avoid overly long cables, as they can degrade signal strength and reduce the system’s overall read performance.

Type of RFID Tag and Form Factor

Select RFID tags that match your environmental and application needs. For example, use on-metal tags for metallic surfaces or washable tags for textiles and garments. The right material and form factor ensure consistent read performance and tag durability.

Correct position assessment for the RFID tag on the asset is also crucial; consistently place tags on similar locations across all items to standardize read performance. Avoid placing tags near metal or liquid unless they are specially designed, as such surfaces can interfere with signal strength and accuracy.

Before full deployment, test tag readability using your specific RFID reader setup. This ensures compatibility between tags and hardware, helping you identify and fix potential issues in real-world conditions before they impact operations.

Reader Firmware & Software Configuration

Proper firmware and software setup enhances RFID system performance by defining virtual read zones and applying tag filters, such as EPC prefixes, to capture only relevant data. Adjusting sensitivity and read rates helps balance performance in various environments—high for fast-moving items, lower for accuracy. Enable edge logic for local processing and use middleware to streamline data. Regular health monitoring and alert systems ensure continuous reliability.

Testing and Calibration

Power Settings Tuning: Calibrate the reader’s power output to match your read zone precisely. Start with low power and gradually increase as needed to reduce the chance of stray reads from nearby zones or unintended tags.

Read Range and Coverage Testing: Physically walk through the read zones while moving tagged items at different angles and speeds. This helps confirm reliable detection across all areas and mimics actual operational conditions.

Tag Read Rate and Missed Reads: Measure how many tags the reader can capture per second, and note areas where tags are consistently missed. These gaps may indicate the need for antenna repositioning or sensitivity adjustment.

Troubleshooting Interference Issues: Use spectrum analyzers or built-in reader diagnostics to identify signal interference or noise sources. Based on findings, adjust reader power levels or reposition antennas to improve clarity and reliability.

Common Mistakes to Avoid

Avoid placing RFID readers too close or too far apart, as it can cause signal overlap or missed reads. Failing to consider environmental elements like metal, water, or heat may disrupt performance. Also, using low-quality or overly long cables reduces signal strength. Always conduct thorough testing before going live to ensure reliability.

Conclusion

Correct installation of RFID readers is essential to unlock the full potential of your RFID system. From choosing the right hardware and positioning it smartly to configuring the software and testing performance, each step directly affects your read accuracy.

Treat installation as an ongoing process that evolves with your business needs. Revisit your setup periodically, especially when scaling or making changes to the environment.

Frequently Asked Questions (FAQs)

Why is proper RFID reader installation critical for system performance?

Correct installation ensures maximum read accuracy, minimizes interference, and prevents missed or stray reads.

What types of RFID readers are commonly used?

The blog highlights fixed readers, handheld readers, integrated readers, and reader modules, each suited for different applications.

What should be considered before deploying RFID readers?

A site assessment, mapping tag paths, checking for interference, and evaluating environmental factors are essential steps.

How does tag density and orientation affect RFID reader performance?

High tag density can cause collisions, so anti-collision logic and sensitivity adjustments are recommended. Orientation consistency also improves accuracy.

What are the best practices for planning read zones?

Ensure slight overlaps between zones to avoid blind spots, but avoid excessive coverage to prevent duplicate reads.

How should RFID tags be selected and positioned?

Tags must match the environment and asset type (e.g., on-metal tags for metallic surfaces). Consistent placement across items ensures standardized reads.

Recent Posts

-

How RFID Portals Transform Logistics & Warehousing Efficiency

Introduction Running a warehouse or logistics operation is no small task. Every day, teams manage sh …Feb 11th 2026 -

Most Common RFID Label Sizes and Their Applications

Introduction Radio Frequency Identification has become a cornerstone of modern tracking and inventor …Feb 2nd 2026 -

RFID Readers Buying Guide — Everything You Need to Know

Introduction Radio Frequency Identification (RFID) is a technology that uses radio waves to identify …Jan 19th 2026