RFID Tunnel in Manufacturing: Speed Meets Accuracy

In today’s manufacturing world, speed and accuracy aren’t just goals—they’re survival essentials. The faster products move through the production line, the quicker they reach customers. But speed means little if accuracy suffers, leading to costly errors, rework, or inventory mismatches.

Radio Frequency Identification (RFID) has become a game-changer for manufacturing by automating tracking, reducing errors, and improving visibility. Among the most impactful RFID solutions are RFID tunnels, designed to capture data automatically as items move along conveyor belts—delivering both speed and precision without slowing down operations.

This article will explain what RFID tunnels are, how they work, their benefits, and why they’re becoming a must-have in modern manufacturing.

What is an RFID Tunnel?

An RFID tunnel is an automated checkpoint that uses RFID readers, antennas, and software integrated with conveyor systems to scan tagged items as they move through. The readers capture tag data, antennas transmit signals, and software processes the information, ensuring real-time tracking. Conveyor integration synchronizes movement and scanning, enabling seamless, fast, and accurate data collection.

How They Work:

As items with RFID tags move through the conveyor, the antennas pick up their unique ID data in real time. The system automatically validates, records, and sends the data to enterprise software such as ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems)—no stopping or manual scanning needed.

Compared to Other Systems:

- Handheld RFID Readers – Good for spot checks, but slower and labor-intensive.

- Fixed RFID Gates – Similar in concept but often used at entry/exit points, not integrated with conveyor flow.

- Tunnel Portals – Continuous, automated, and optimized for high-volume environments.

The Role of RFID Tunnel in Manufacturing

Manufacturers live in a just-in-time (JIT) world, where delays can ripple through the supply chain. Tunnel portals keep materials moving without bottlenecks.

Minimized Delays

RFID tunnel eliminates manual scanning pauses by reading items automatically as they pass, ensuring smooth product flow and reducing costly production line slowdowns.

High Throughput

Designed for high-volume environments, these portals can process hundreds or thousands of tagged items per hour, making them ideal for just-in-time (JIT) manufacturing systems.

Improved Accuracy

By validating items in real time, RFID portals ensure the right products move forward in the workflow, preventing mix-ups and costly rework in manufacturing operations.

Enhanced Worker Productivity

Automating tracking tasks frees employees from repetitive manual scanning, allowing them to focus on higher-value activities such as quality checks, maintenance, or process improvements.

Example: A mid-sized electronics plant reduced order processing time by 30% after adopting an RFID tunnel, enabling faster fulfillment, fewer bottlenecks, and greater supply chain efficiency.

Ensuring Accuracy with RFID

Speed is worthless if errors creep in. RFID tunnel ensure precision tracking.

- Reduced Human Error: No manual barcode scanning means fewer missed items or wrong entries.

- Real-Time Validation: Systems instantly verify if an item is in the right batch, order, or sequence.

- Improved Accuracy Rates: Manufacturers often report over 99% read accuracy when portals are correctly configured.

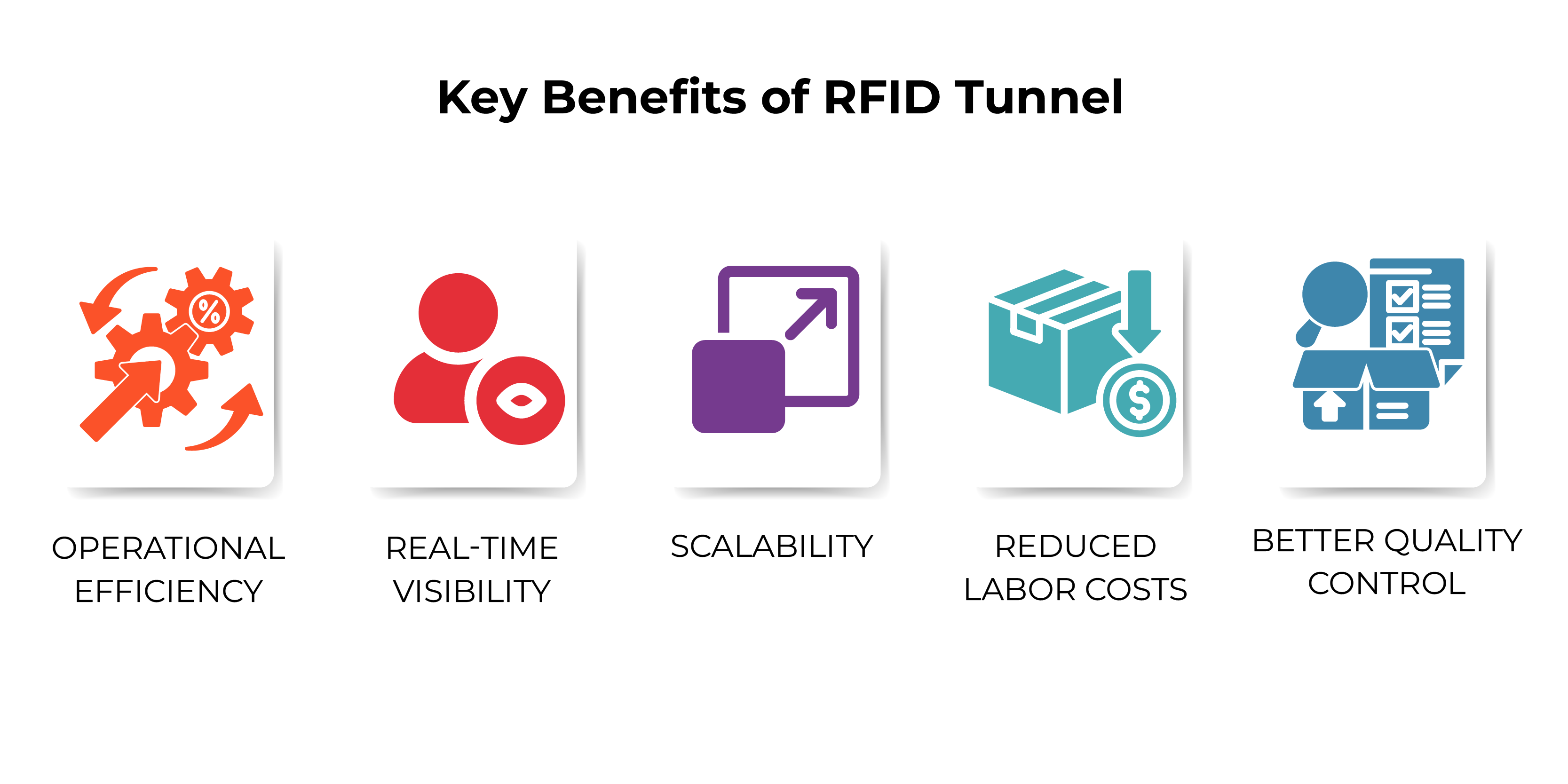

Key Benefits of RFID Tunnel

Operational Efficiency

RFID tunnel automates data capture, ensuring uninterrupted production flow. This reduces delays, minimizes errors, and allows workers to focus on critical, higher-value manufacturing tasks.

Real-Time Visibility

Instant access to live tracking data enables managers to make faster, informed decisions about inventory, shipments, and production needs, preventing shortages and improving supply chain responsiveness.

Scalability

These portals can be quickly adapted for new production lines, varying product sizes, or layout changes, making them a flexible solution for growing and evolving manufacturing operations.

Reduced Labor Costs

By reducing dependence on manual barcode scanning, RFID portals lower staffing needs, streamline repetitive tasks, and cut operational expenses without sacrificing accuracy or efficiency.

Better Quality Control

With real-time validation at every stage, RFID portals help detect misplaced or incorrect items immediately, improving quality assurance and reducing costly rework in the process.

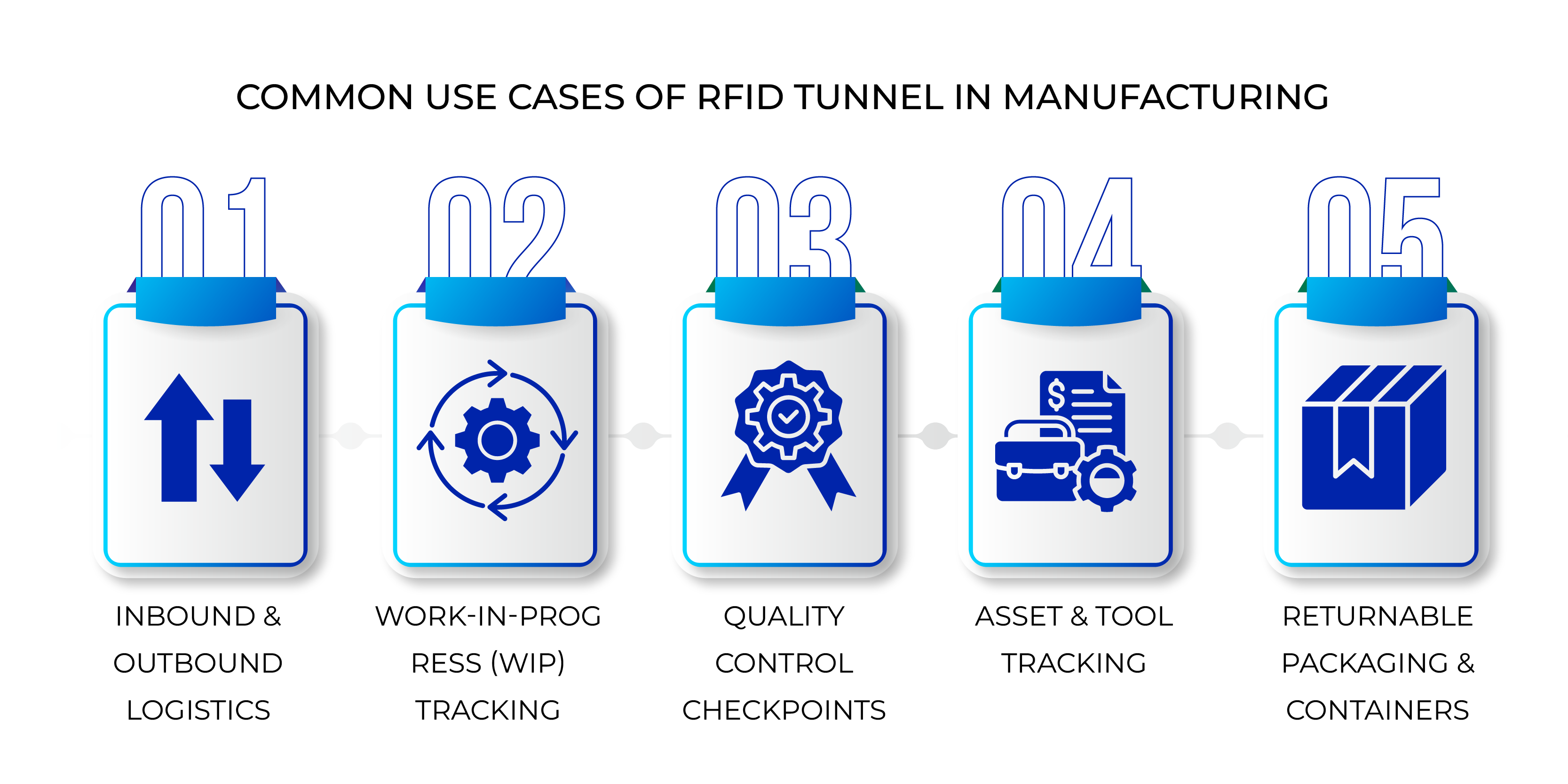

Common Use Cases in Manufacturing

Inbound and Outbound Logistics

RFID tunnel automatically scans tagged pallets and cartons during receiving or dispatch. This ensures every shipment matches purchase orders or sales orders, preventing discrepancies and reducing time spent on manual checks at dock doors.

Work-in-Progress (WIP) Tracking

As components move along conveyors, RFID portals track each part or subassembly in real time. This visibility helps supervisors confirm production flow, detect bottlenecks, and ensure materials are available at the right stage without delays.

Quality Control Checkpoints

RFID portals placed before inspection stations confirm that only the correct items move forward. If a mismatched or missing component is detected, alerts trigger immediately, preventing defective products from reaching packaging or final assembly lines.

Asset & Tool Tracking

High-value tools and equipment passing through portals are instantly logged, ensuring they’re available when needed and not misplaced. This minimizes downtime caused by searching for tools and improves overall accountability in the production floor.

Returnable Packaging and Containers

Reusable bins, crates, or trolleys equipped with RFID tags are tracked at portals, ensuring they are returned to the right location. This reduces loss, supports sustainability, and maintains smooth material handling operations.

Implementation Considerations

1. Selecting Hardware & Software

Start by matching RFID readers and antennas to your conveyor’s speed, tag type, and product mix. For fast-moving lines, choose high-performance readers with multiple antenna ports. Pair them with RFID middleware and software that can filter duplicate reads, push data directly into ERP/MES, and scale as operations expand.

2. Portal Placement

Positioning is critical. Antennas should cover the full conveyor width and height, leaving no blind spots. In my experience, it’s best to test with different product types—cartons, metal parts, liquids—to fine-tune placement. Mount antennas at slight angles to improve read consistency as tags move past.

3. System Integration

RFID portals only add value if data flows seamlessly into existing systems. Integrate with ERP or MES to update WIP status, inventory counts, or shipping records automatically. This eliminates manual entry, enables real-time dashboards, and ensures managers always see accurate data for faster decision-making.

4. Interference Management

Metal parts, liquids, and environmental noise often reduce read reliability. To counter this, use shielding panels, select tags designed for challenging materials, and fine-tune antenna power levels. It’s important to run onsite testing under real production conditions before full deployment.

5. Tagging Strategy

Decide early where RFID tags will be applied—on products, cases, pallets, or returnable containers. Consistent placement improves readability. In my experience, testing multiple tag positions before rollout prevents future headaches on the shop floor.

6. Maintenance & Monitoring

Like any system, RFID portals need upkeep. Set up alerts to monitor reader health, network connectivity, and read performance. Regular preventive checks ensure portals keep running smoothly without disrupting conveyor operations.

Challenges and Mitigation Strategies

- Tag Placement & Orientation: Tags should face the antennas for consistent reads. Testing with different product types helps identify the most reliable placement before full-scale deployment.

- Environmental Factors: Install shielding or use specialized tags to reduce interference caused by metals, liquids, or electrical noise in the manufacturing environment.

- Data Overload: Large volumes of tag reads can overwhelm systems if not managed. Using advanced software like TagMatiks RFID Software ensures duplicate reads are filtered, data is validated, and only actionable information flows into ERP or MES systems.

Future Outlook

The future of the RFID Tunnel in manufacturing is driven by intelligent technologies. With AI and machine learning, systems can predict bottlenecks or supply shortages before they occur, allowing proactive decision-making. As IoT convergence grows, RFID will integrate with sensors to deliver richer, real-time insights across the production floor. Additionally, predictive analytics will harness RFID data to anticipate equipment maintenance needs and forecast production requirements, enabling manufacturers to optimize efficiency, reduce downtime, and stay ahead of operational challenges.

Conclusion

RFID tunnel represents the perfect blend of speed and accuracy in modern manufacturing. They allow goods to flow faster without sacrificing data quality, helping manufacturers meet tight deadlines, improve quality, and keep costs under control.

For businesses aiming to stay competitive, evaluating RFID tunnel could be the next step toward a more resilient and efficient operation.

Frequently Asked Questions (FAQs)

What is an RFID tunnel in manufacturing?

An RFID tunnel is a specialized enclosure equipped with RFID readers and antennas that automatically scans tagged items as they pass through, enabling fast and accurate data capture.

How does an RFID tunnel improve manufacturing processes?

It allows bulk scanning of multiple items simultaneously, reducing manual effort, increasing speed, and ensuring precise tracking of components.

Why is accuracy critical in RFID tunnel applications?

Accurate reads prevent miscounts, duplicate scans, and production errors, ensuring smooth workflows and reliable inventory data.

Where are RFID tunnels typically installed in manufacturing facilities?

They are commonly placed at production lines, packaging stations, and quality control checkpoints, ensuring seamless visibility of parts and products.

Can RFID tunnels reduce labor costs in manufacturing?

Yes. By automating scanning, RFID tunnels minimize manual handling, reduce cycle times, and lower overall labor expenses.

How do RFID tunnels support quality control?

They ensure that only correctly tagged and verified items move forward, reducing defects and improving compliance with manufacturing standards.

What are the key benefits of RFID tunnels for manufacturers?

Benefits include faster production throughput, reduced errors, improved accuracy, better compliance, and enhanced operational efficiency.

Recent Posts

-

What Is an RFID Self-Checkout System? A Complete Guide for Retailers

Introduction Retail checkout has seen a remarkable transformation over the years. What started with …Feb 27th 2026 -

Upgrade from Barcodes to RFID on Shopify: A Retailer’s Guide

Retailers on Shopify are beginning to question whether barcodes are enough. With rising customer exp …Feb 24th 2026 -

Work-in-Progress Tracking with RFID in Manufacturing

Introduction In manufacturing, Work-in-Progress (WIP) refers to items that are in various stages of …Feb 20th 2026