Which RFID Tags Work Best on Metal Surfaces

Introduction

RFID technology has revolutionized asset tracking and inventory management. However, when it comes to metal surfaces, traditional RFID tags often fall short. Metal interferes with radio frequency signals, leading to unreliable reads and data inaccuracies. This challenge is particularly critical in industries like manufacturing, oil & gas, IT, and healthcare, where metal assets are prevalent.

In this blog, we'll delve into why standard RFID tags struggle on metal, explore the design of on-metal RFID tags, and highlight top tag types and product suggestions for various metal-based applications.

What Are On-Metal RFID Tags?

On-metal RFID tags are specially engineered to function efficiently on or near metal surfaces. They incorporate design elements such as spacers or foam backing, encapsulation in durable materials, and modified antenna structures to mitigate interference from metal. Common features include high read range on metal, rugged construction, and compatibility with UHF RFID.

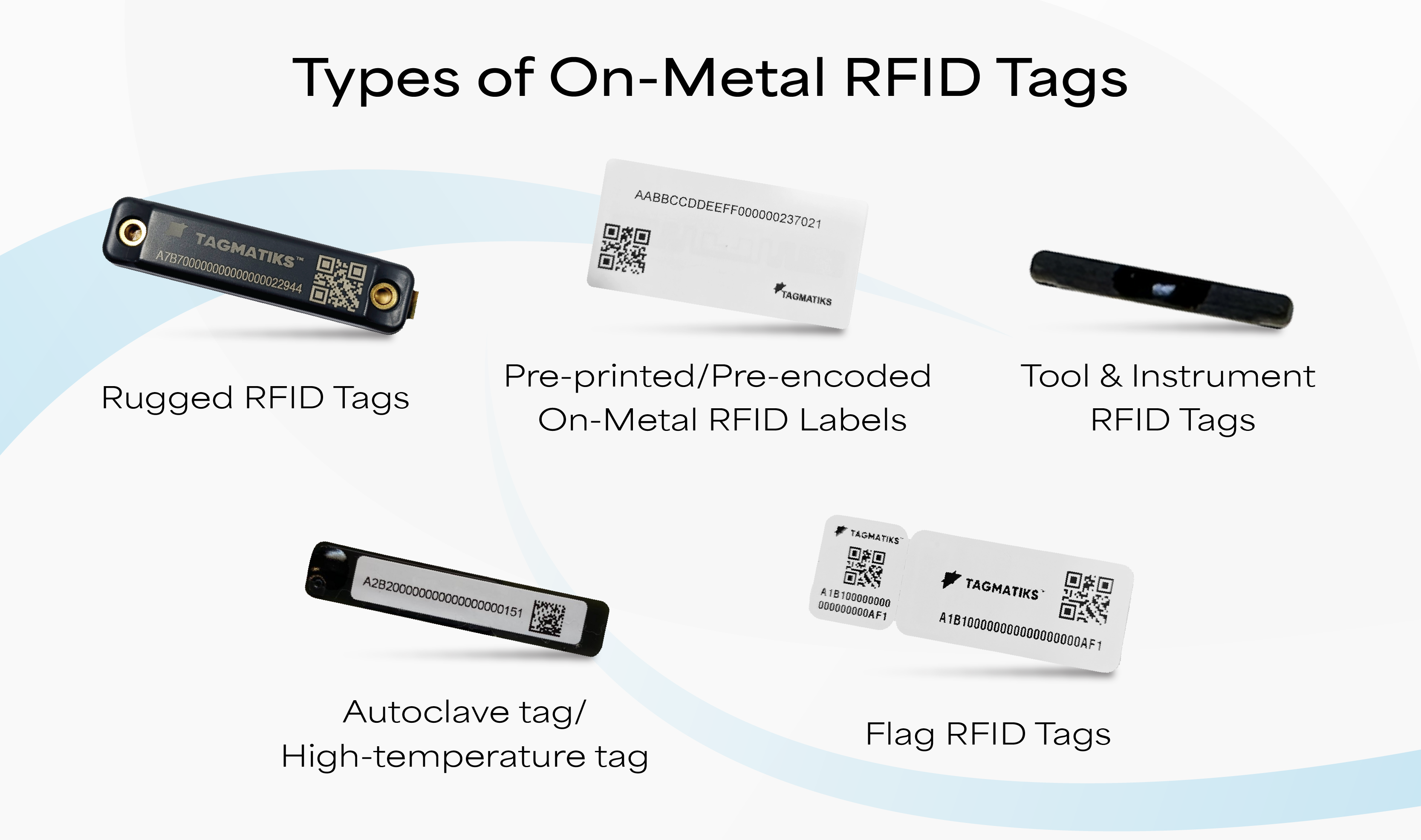

Types of On-Metal RFID Tags

Rugged RFID Tags

Rugged on-metal RFID tags are engineered for tough industrial environments. The TagMatiks Gorilla Square RFID Tag is impact-resistant, weatherproof, and delivers dependable performance on metal equipment and heavy machinery.

Pre-printed/Pre-encoded On-Metal RFID Labels

Pre-printed on-metal RFID labels are ideal for fast application and easy identification. TagMatiks Pre-printed On Metal RFID Labels come ready-to-use and offer accurate reads when applied to curved or flat metal surfaces.

Tool & Instrument RFID Tags

Compact and resilient, these tags are designed for tight spaces and frequent handling. The TagMatiks Tool & Instrument RFID Tag is perfect for tracking metal hand tools and surgical instruments.

Autoclave Tolerant UHF RFID Tags

These RFID tags endure repeated sterilization, making them suitable for healthcare and lab use. The TagMatiks Autoclave Tolerant UHF RFID Tag resists heat, pressure, and chemicals during autoclaving cycles.

High-Temperature On-Metal Tags

Used in extreme heat environments like furnaces or foundries, these tags remain readable under intense conditions. TagMatiks High Temperature RFID Labels and Tags perform reliably on hot metal surfaces without signal loss.

Flag RFID Tags

Flag-style RFID tags are designed to minimize interference from metal by extending the antenna away from the surface. These tags partially float above the metal, making them ideal for curved or uneven metal surfaces where direct contact may hinder performance. Flag tags are commonly used in manufacturing, IT asset tracking, and maintenance workflows where flexibility and readability are essential.

Use Cases and Industry Applications

IT Asset Tracking

In data centers, IT assets like servers, laptops, and routers are often enclosed in metal casings that disrupt traditional RFID signals. On-metal RFID tags solve this issue by providing accurate tracking without interfering with sensitive electronics, improving visibility and streamlining audits and asset maintenance processes.

Manufacturing & Industrial Equipment

Heavy-duty environments like manufacturing plants demand robust tagging solutions. On-metal RFID tags are designed to withstand high temperatures, vibrations, and rough handling while providing reliable identification and traceability of machines, tools, and parts mounted on or made of metal.

Oil & Gas Pipelines and Cylinders

Pipelines and metal cylinders in the oil and gas sectors require tags that can perform in curved, metallic, and outdoor environments. On-metal RFID tags are engineered to resist harsh elements like pressure, temperature fluctuations, and corrosion, ensuring durable and accurate asset tracking.

Healthcare Equipment

Hospitals and laboratories rely on metal carts and sterilized instruments that undergo autoclaving and exposure to harsh chemicals. Specialized on-metal RFID tags maintain functionality through these sterilization cycles, enabling effective tracking and inventory control of critical medical tools and stainless-steel equipment.

Warehouse Racks and Shelving

Inventory stored on metal racks and shelving can be difficult to track using standard tags due to interference. On-metal RFID tags allow for precise, long-range readability, helping retailers and distributors improve inventory visibility, accelerate cycle counts, and enhance warehouse efficiency across metal storage systems.

Installation Tips for On-Metal RFID Tags

Clean and Dry the Surface: Always clean and dry the metal surface before applying the tag to remove dust, oil, or moisture. This ensures secure adhesion and prevents tag detachment over time.

Use Correct Adhesive: Press the tag firmly or use a manufacturer-recommended adhesive to keep it securely in place. Proper attachment is essential for consistent read performance and durability in harsh conditions.

Consider Tag Orientation: Align the RFID tag in the recommended orientation to optimize signal strength. Improper placement can reduce the read range or cause the tag to be unreadable during scanning.

Use Compatible RFID Readers: Make sure your RFID readers are configured for the type and frequency of the on-metal tags. Reader-tag compatibility directly affects the read distance and system reliability.

Note: Some on-metal RFID tags are designed to be mounted using screws or rivets instead of adhesive, especially in rugged or industrial environments.

Common Mistakes to Avoid

Avoid Using Standard RFID Tags on Metal

Standard tags don’t perform well on metal and may fail to read entirely. Always use specialized on-metal tags designed to handle reflective interference and metal proximity.

Don't Place Tags Too Close Together

Placing on-metal tags too closely can create signal interference, resulting in missed reads or duplicate scans. Maintain adequate spacing based on manufacturer guidelines to ensure performance.

Account for Environmental Conditions

High temperatures, moisture, or vibration can degrade tag adhesion or electronics. Choose tags rated for specific environmental conditions to avoid performance issues or damage over time.

Don’t Skip Testing Before Deployment

Failing to test in the actual application environment may lead to system errors later. Pilot testing helps identify issues early and ensures smooth operation at scale.

Conclusion

Not all RFID tags are created equal—metal surfaces demand specialized tags for reliable tracking and performance. Choosing the right tag based on your application, environment, and metal surface type is crucial to maximize efficiency and ROI.

Recent Posts

-

Which RFID Tags Work Best on Metal Surfaces

Introduction RFID technology has revolutionized asset tracking and inventory management. However, wh …May 19th 2025 -

How RFID Retailers Are Cutting Costs and Boosting Profits

Introduction Retailers today are under pressure to do more with less. Rising labor costs, increasing …May 16th 2025 -

What are the different RFID structures, and their use cases?

Introduction RFID is a powerful technology that uses electromagnetic fields to automatically identif …May 12th 2025